1. Neglecting Regular Maintenance:

Failing to schedule regular maintenance can lead to elevator breakdowns and safety hazards. Regular inspections and maintenance checks are essential to keep elevators running smoothly.

2. Ignoring Safety Protocols:

Beginners must familiarize themselves with safety protocols and regulations governing elevator operations. Ignoring safety procedures can result in accidents and legal liabilities.

3. Improper Load Management:

Overloading elevators beyond their weight capacity can strain the equipment and pose safety risks. Beginners should adhere to weight limits and educate users on proper load management.

4. Skipping Training Programs:

Proper training is essential for elevator technicians and operators. Beginners should undergo comprehensive training programs to understand the equipment, safety procedures, and troubleshooting techniques.

5. Neglecting Emergency Preparedness:

Failure to have an effective emergency response plan can jeopardize passenger safety during emergencies like power outages or mechanical failures. Beginners should develop and practice emergency protocols regularly.

6. Misinterpreting Error Codes:

Ignoring or misinterpreting error codes displayed on elevator control panels can lead to delayed repairs and further damage. Beginners should promptly address error codes and seek professional assistance if needed.

7. Ignoring Component Wear and Tear:

Components like cables, doors, and control systems can wear out over time. Beginners should regularly inspect and replace worn-out components to prevent malfunctions and accidents.

8. Improper Lubrication:

Lack of proper lubrication can cause elevator components to malfunction and increase friction, leading to premature wear and tear. Beginners should follow manufacturer guidelines for lubricating elevator parts.

9. Inadequate Communication:

Effective communication is crucial in the elevator industry, especially during maintenance, repairs, and emergencies. Beginners should maintain clear communication channels with team members, building management, and users.

10. Ignoring Feedback and Updates:

Technology and safety standards in the elevator industry evolve over time. Beginners should stay updated with industry trends, feedback from users, and equipment upgrades to ensure optimal performance and safety.

By avoiding these common mistakes, beginners in the elevator industry can enhance safety, prolong equipment lifespan, and improve overall operational efficiency. Continuous learning, adherence to safety protocols, and proactive maintenance are key factors in successful elevator management.

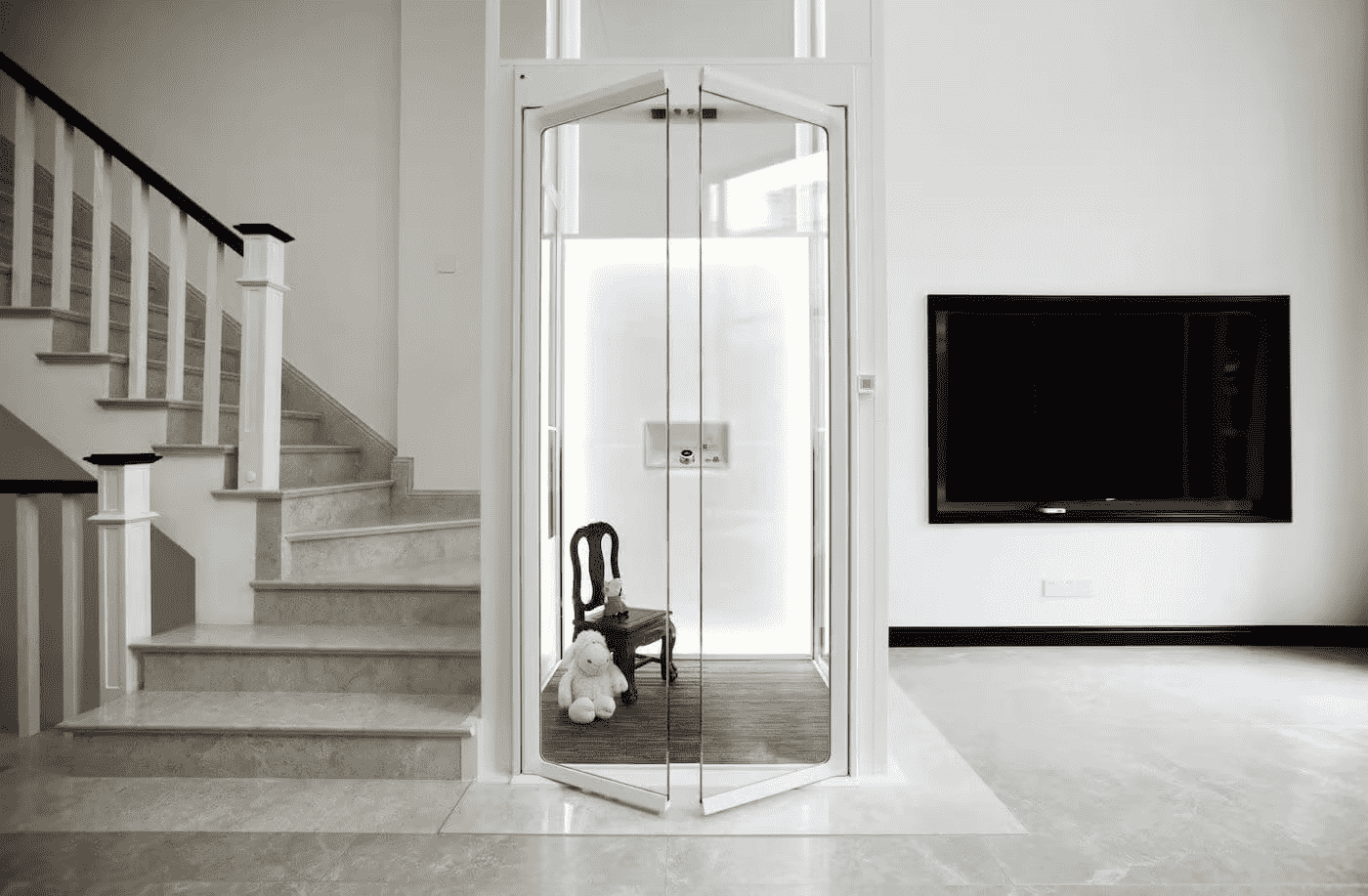

As a leading best elevators manufacturer, avoiding the top 10 mistakes made by beginners in the elevator industry is crucial for ensuring safety, efficiency, and longevity of elevator systems. By prioritizing regular maintenance, adhering to safety protocols, and investing in comprehensive training programs, beginners can mitigate risks, prevent accidents, and improve overall elevator performance.

Furthermore, staying updated with industry trends, technology advancements, and regulatory requirements is essential for continuous improvement in elevator management. By learning from common mistakes and implementing best practices, beginners can contribute to a safer and more reliable elevator experience for users, building owners, and maintenance teams alike.

Diana Torres

Rassa id neque aliquam vestibulum morbi blandit in fermentum et sollicitudin ac orci phasellus egestas tellus velit ut tortor pretium viverra suspendisse potenti nullam ac tortor eu turpis egestas pretium.

Diana Torres

Rassa id neque aliquam vestibulum morbi blandit in fermentum et sollicitudin ac orci phasellus egestas tellus velit ut tortor pretium viverra suspendisse potenti nullam ac tortor eu turpis egestas pretium.

Diana Torres

Rassa id neque aliquam vestibulum morbi blandit in fermentum et sollicitudin ac orci phasellus egestas tellus velit ut tortor pretium viverra suspendisse potenti nullam ac tortor eu turpis egestas pretium.